In the dynamic landscape of global electronics manufacturing, Poland has emerged as a pivotal hub for companies seeking efficiency, quality, and innovation. This article delves into the myriad benefits of producing electronics in Poland, exploring key aspects such as cost-effectiveness, strategic location, advanced manufacturing capabilities, and the country's commitment to quality and sustainability.

Introduction

- Brief overview of global electronics manufacturing trends.

- The growing prominence of Poland in the electronics manufacturing industry.

- Why this topic matters to businesses in the UK and globally.

1. Understanding Electronics Manufacturing in Poland

- Definition of key terms: PCBA, EMS, SMT, THT, and box building.

- Overview of Poland’s economic environment for the electronics industry.

- Key benefits of outsourcing to Poland.

2. Advantages of Producing Electronics in Poland

2.1. Cost Efficiency

- Lower production and operational costs compared to Western Europe.

- Access to a highly skilled yet affordable workforce.

2.2. Strategic Location

- Poland’s geographical position in the heart of Europe.

- Proximity to major markets in the EU, UK, and beyond.

2.3. Advanced Manufacturing Capabilities

- Overview of state-of-the-art facilities and technologies in Poland.

- Expertise in SMT (Surface Mount Technology) and THT (Through-Hole Technology).

- Contract electronics manufacturing and its growth in Poland.

2.4. Robust Supply Chain and Logistics

- Integration with the EU’s logistics network.

- Access to raw materials and components.

3. Quality and Standards in Polish Electronic Manufacturing

- Compliance with international certifications (e.g., ISO 9001, IPC standards).

- Emphasis on quality assurance and testing protocols.

- Case studies of successful electronics manufacturing projects in Poland.

4. Services Offered by Polish EMS Providers

4.1. PCB Assembly (PCBA)

- Steps in the PCB assembly process: SMT, THT, and testing.

- Importance of precision and expertise in PCBA.

4.2. Box Building

- Overview of box building and its importance in product completion.

- Poland’s edge in delivering complete electronic product solutions.

4.3. Prototyping and Customization

- Rapid prototyping services in Poland.

- Tailored solutions for diverse industries (e.g., automotive, healthcare, IoT).

5. The Role of Innovation in Poland’s Electronics Industry

- Growth of R&D in Poland.

- Government incentives for innovation and manufacturing.

- Collaborations between EMS providers and tech start-ups.

6. Sustainable and Ethical Manufacturing in Poland

- Focus on eco-friendly production processes.

- Poland’s commitment to reducing electronic waste.

7. Success Stories - Why Businesses Choose Poland

- Examples of global companies partnering with Polish EMS providers.

- Testimonials highlighting cost savings and quality.

8. How to Get Started with Electronics Manufacturing in Poland

- Steps to choose the right EMS partner in Poland.

- Factors to consider: expertise, certifications, and client reviews.

1. Understanding Electronics Manufacturing in Poland

1.1. Key Terminologies

PCBA (Printed Circuit Board Assembly): The process of soldering or assembling electronic components onto a PCB.

EMS (Electronics Manufacturing Services): Comprehensive services that include design, assembly, testing, and distribution of electronic components and assemblies.

SMT (Surface Mount Technology): A method for producing electronic circuits where components are mounted directly onto the surface of PCBs.

THT (Through-Hole Technology): An older method of mounting components by inserting leads through holes in the PCB and soldering them in place.

Box Building: The complete assembly of electronic systems, including PCBA, enclosures, cables, and other components, resulting in a finished product.

1.2. Poland's Economic Environment for Electronics Manufacturing

Poland's electronics sector has experienced significant growth, with a sales value reaching 44.23 billion PLN in 2020, marking a 6.0% year-over-year increase. The industry employs approximately 62,500 individuals, underscoring its substantial role in the national economy.

1.3. Benefits of Outsourcing to Poland

Outsourcing electronics manufacturing to Poland offers numerous advantages, including cost savings, access to a skilled workforce, and proximity to major European markets. The country's commitment to quality and adherence to international standards make it an attractive destination for electronics production.

2. Advantages of Producing Electronics in Poland

2.1. Cost Efficiency

Poland offers lower labor costs compared to Western Europe, providing significant savings without compromising quality. The country's favorable economic conditions and competitive pricing make it an ideal location for electronics manufacturing.

2.2. Strategic Location

Situated in Central Europe, Poland provides easy access to major markets within the EU and the UK. Its well-developed infrastructure facilitates efficient logistics and distribution across the continent.

2.3. Advanced Manufacturing Capabilities

Polish EMS providers utilize state-of-the-art technologies, including SMT and THT, to deliver high-quality electronic assemblies. The country's expertise in contract electronics manufacturing has attracted numerous global companies seeking reliable partners.

2.4. Robust Supply Chain and Logistics

Poland's integration with the EU's logistics network ensures seamless supply chain operations. The country's access to raw materials and components further enhances its manufacturing capabilities.

3. Quality and Standards in Polish Electronic Manufacturing

Polish manufacturers adhere to international certifications such as ISO 9001 and IPC standards, ensuring high-quality production. Rigorous quality assurance and testing protocols are in place to meet global industry requirements.

4. Services Offered by Polish EMS Providers

4.1. PCB Assembly (PCBA)

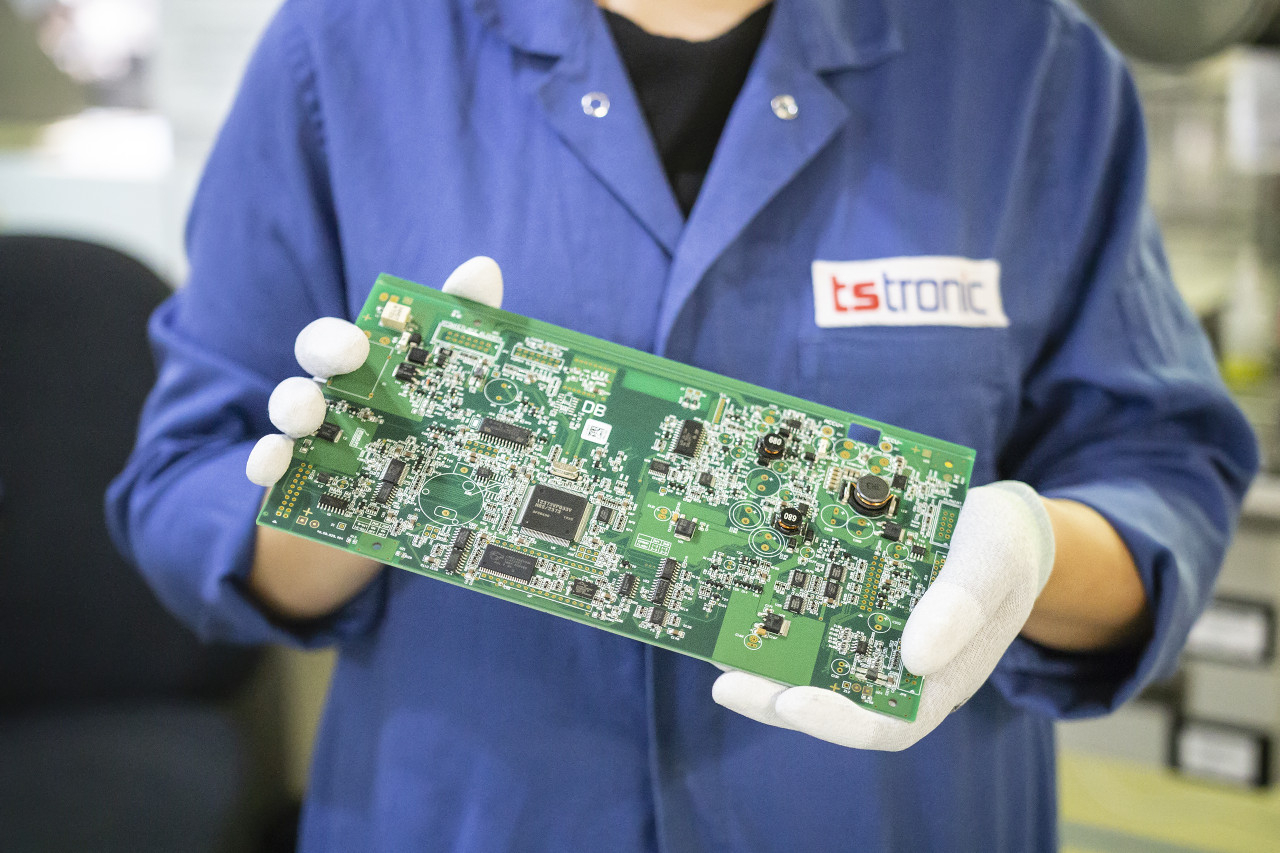

Polish EMS companies excel in PCBA, employing advanced SMT and THT techniques to assemble complex electronic circuits with precision.

4.2. Box Building

Comprehensive box building services include the integration of PCBs, enclosures, and other components, resulting in fully assembled electronic products.

4.3. Prototyping and Customization

Rapid prototyping services enable quick development and testing of new designs, while customization options cater to specific client requirements across various industries.

5. The Role of Innovation in Poland’s Electronics Industry

Poland's electronics sector is characterized by continuous innovation, supported by government incentives and collaborations between EMS providers and tech startups. This fosters the development of cutting-edge technologies and solutions.

6. Sustainable and Ethical Manufacturing in Poland

Polish manufacturers prioritize eco-friendly production processes and are committed to reducing electronic waste, aligning with global sustainability trends.

7. Success Stories: Why Businesses Choose Poland

Numerous global companies have partnered with Polish EMS providers, benefiting from cost savings, high-quality production, and timely delivery. These collaborations highlight Poland's strengths in the electronics manufacturing sector.

8. How to Get Started with Electronics Manufacturing in Poland

To select the right EMS partner in Poland, consider factors such as expertise, certifications, and client reviews. Engaging with established companies like TSTRONIC can provide a seamless transition into the Polish manufacturing landscape.

Poland's strategic advantages in electronics manufacturing—including cost efficiency, skilled labor, advanced technologies, and a commitment to quality—make it an ideal destination for companies seeking to enhance their production capabilities. Partnering with reputable Polish EMS providers (like TSTRONIC) can lead to successful and sustainable manufacturing outcomes.

What are the key benefits of PCBA in Poland? Poland offers high-quality PCBA services with cost-effective solutions, leveraging advanced technologies and skilled labor.

How does Poland ensure quality in electronics manufacturing? Manufacturers adhere to international standards such as ISO 9001 and implement rigorous quality assurance protocols.

Can Polish EMS providers handle large-scale production? Yes, with state-of-the-art facilities and scalable operations, Polish EMS providers can manage both small and large-scale productions.

What is the role of SMT and THT in electronics manufacturing? SMT and THT are crucial assembly techniques used to mount components onto PCBs, each suited for different types of components and applications.

How competitive are Polish EMS services compared to other countries? Polish EMS services are highly competitive, offering a balance of quality, cost efficiency, and strategic location advantages.